Service

RELIABILITY IS OUR GOAL

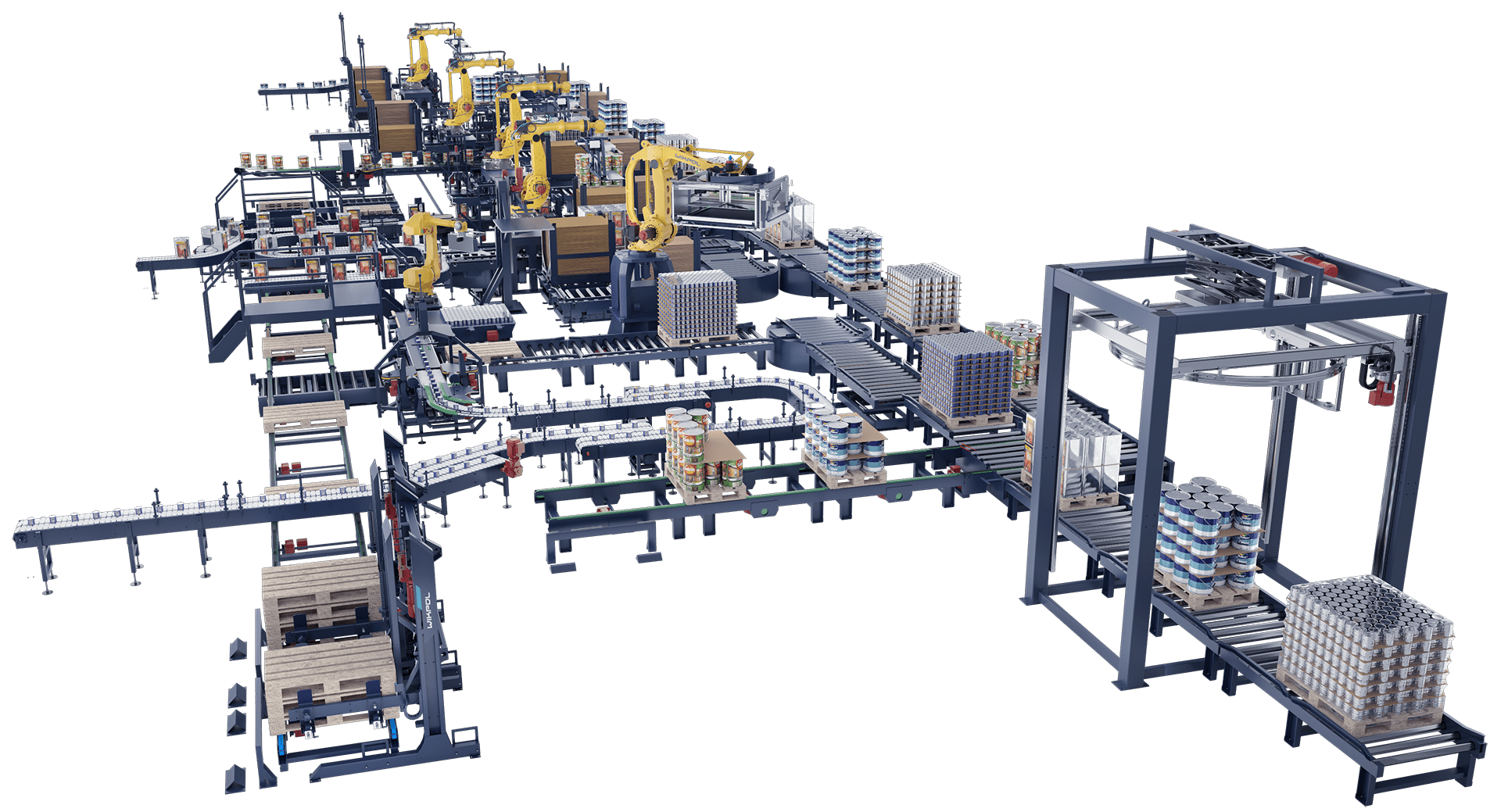

We make any possible effort for our robotized systems to meet the expectations of the users and help effectively complete their production tasks.

We offer a full range of maintenance services, which we perform remotely via a safe VPN connection, or at the site – at the customer’s plant. Our maintenance crews, comprised of highly qualified engineers, react promptly to notifications transferred by our customers.

Types of service

Do you have any questions?

Service department at your disposal

We work to provide the highest manufacturing standard at every stage of the implementation of the investment project

Round-the-clock reports

Special servicing platform

Remote servicing

Periodic inspections

REMOTE SERVICING 2.0

At the moment, we work to deploy a new function, which constitutes a significant progress in ordering maintenance information – entering, data regarding the status of the equipment and devices automatically and remotely directly to our IT platform.

PROPER OPERATION

The proper operation of the palletizing line, which covers, among others, observing the recommended deadlines for the main and periodical inspections, guarantees a long and trouble-free operation of the devices, while bringing measurable benefits to the users:

- minimizes the problems related to operation maintenance

- reduces the operation maintenance costs

- eliminates spare parts management

- helps plan the production processes precisely