AUTONOMOUS MOBILE ROBOTS

EFFECTIVE TRANSPORT SOLUTION

BENEFITS

RESULTING FROM THE INTRODUCTION OF AUTONOMOUS MOBILE ROBOTS

AMR

AMR

INTUITIVE AND SIMPLE IN OPERATION

Many operations proceed through a webserver:

defining key vehicle parameters

possible reconfiguration of the equipment

room mapping

creating paths

AUTONOMOUS MOBILE ROBOTS

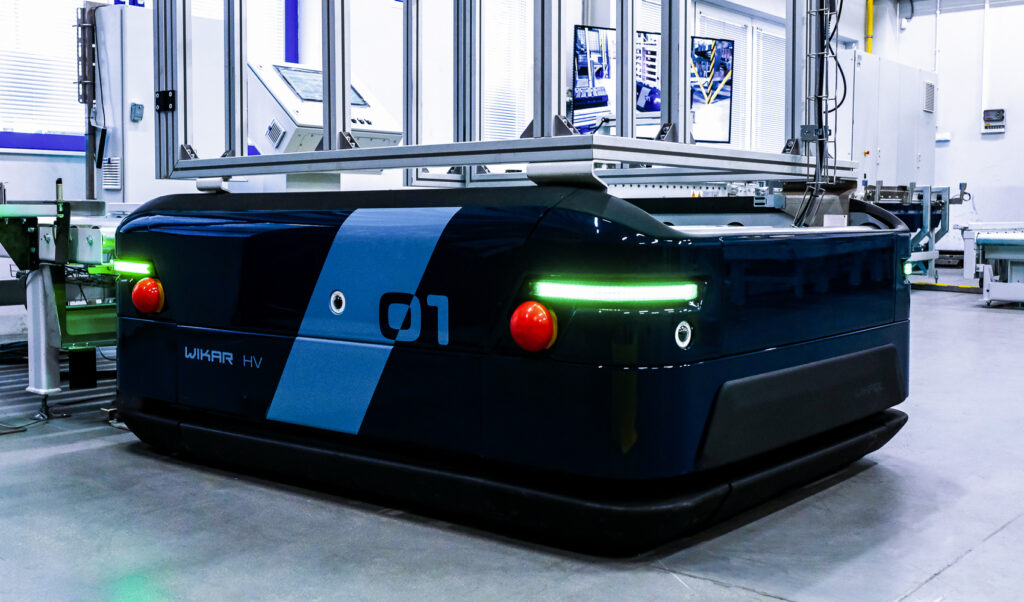

Regardless of the industry in which the manufacturers operate, the efficient flow of materials and finished products plays an important role in production plants. In the case of logistics centers, the transport of goods is critical for ensuring maximum efficiency of processes. For these reasons, high quality WIKAR HV mobile robots available in Wikpol’s offer deserve special attention of enterprises.

WHAT ARE AMR ROBOTS?

AMR autonomous mobile robots (AMR robots, AMR trolleys) are special vehicles that enable the transport of loads over short distances without human intervention. Thanks to a system of laser sensors, cameras and advanced software, the mobile robots are able to process information about their environment and autonomously select the optimal route; also in dynamic environments.

WHAT ARE THE APPLICATIONS OF MOBILE ROBOTS?

AMR robots are a universal means of transport in various types of intralogistics processes, both in production companies and logistics or distribution centers. They are great solution for transporting materials for production, as well as loads on the way to the production line – warehouse, such as piles of full and empty pallets as well as products and containers of large (pallet) dimensions.

HOW DO AUTONOMOUS MOBILE ROBOTS OPERATE?

The operation of AMR robots is based on several basic principles:

- independence

- collecting information from the environment using sensors

- processing of the information acquired

- making decisions based on the results obtained

In the result, mobile robots perform tasks efficiently, thanks to the ability to move along the shortest possible paths and avoid collisions with fixed and moving objects, including people. Optionally, the mobile robots can also interact with the environment through the installed effectors.

CONTROL

Wikar HV mobile robots are equipped with Siemens controls, well known to Polish and European specialists and include components widely available on the market.

WIKAR HV MOBILE ROBOTS — UNDENIABLE ADVANTAGES

WIKAR HV mobile robots manufactured by Wikpol are technically advanced, modern transport vehicles distinguished by their reliability, flexibility, ease of implementation and intuitive operation.

NAVIGATION

Wikpol’s mobile robots use the ANS + Natural Feature navigation, based on the current processing of environmental features. In order to implement the Wikar HV mobile robot, it is not necessary to create or modify the environment and its infrastructure, e.g. by painting traffic paths, attaching mirrors or RFID tags. Thanks to natural navigation, the vhicle calculates its position and follows the programmed routes. Thanks to natural navigation, the mobile robot calculates its position and follows the programmed routes. If it proves impossible to drive along declared path, the trolley has the option of making an alternative route through a defined tunnel of a specified width, in which it can avoid the obstacles encountered. The use of this type of solution translates not only into the possibility of universal applications of the robot, but also into a significant simplification and acceleration of its installation.

In summary, the ANS+ Natural Feature navigation means:

POWER SUPPLY

The energy source of the Wikar HV mobile robot is the LiFePO4 battery, which is characterized by its high durability, safety, power and stability. Its important features also include simple and efficient charging. Wikar HV mobile robots operate smoothly in 24h mode. To this end, several ways of providing energy are envisaged:

- replacement of the battery and the possibility of external charging of the battery

- charging the vehicle at the docking station

- recharging the vehicle while performing tasks

The operating time of the mobile robot on a single charge is 8-12 hours.

SAFETY

Wikar HV has been equipped with an advanced safety system. The most important functions of the system are detecting objects and adjusting the speed and driving dynamics to the changing working environment. In the event of an obstacle, e.g. a human, approaching the AMR trolley, the detection fields of the safety scanners trigger an early reduction in the vehicle’s speed and an optical-acoustic warning. If the distance to the object continues to decrease, they enable a safe protective stop of the AMR. Wikar HV robot safety system also includes:

dynamic selection of protective fields

360⁰ monitoring

emergency buttons for emergency stops

video recording of the robot’s route

load protection cage

reproduction of recorded monitoring events

option: additional illumination of the route (blue)

COMMUNICATION

In the Wikar HV mobile robot, we utilized the Siemens Scalance communication modules, with the help of which PROFINET wireless communications are implemented. The implemented system, thanks to the web server mediation, allows remote diagnostics of the AMR trolley, mapping and simple map corrections, as well as parameterization and reconfiguration of the vehicle.

WHY IS THE WIKAR HV MOBILE ROBOT A GREAT CHOICE?

The Wikar HV mobile robot is characterized by a wide range of applications, which results from a number of solutions facilitating its operation and operation, such as:

easy integration with palletizing systems

possible different levels of the working plane

intuitive, simple operation – using smartphone, tablet

required programming reduced to a minimum

optional manual control

easy scalability (expansion)

easy access to the control cabinet

extended service life of crucial components

simple battery replacement or automatic battery charging

use of generally available industrial automation components

real-time vehicle / fleet management

dynamic assignment of tasks depending on the priority and availability of fleet resources

The high usefulness of Wikar HV mobile robots in intralogistics areas is also due to the possibility of using them together with traditional, human-operated transport devices. Thanks to their features, Wikar HV mobile robots greatly contribute to optimizing the flow of materials, and thus to improving the efficiency and competitiveness of enterprises.

MAINTENANCE

In addition to the service provided at the customer’s plant, Wikpol carries out remote diagnostics thanks to secure access to the robot’s PLC. The manufacturer also has the ability to remotely configure AMRs

from the level of web server. A new feature is the remote connection of mobile robots with the Wikpol service platform. The robot collects its diagnostic data and reports emerging incidents in the system by attaching the diagnostic buffer of the PLC.

For users, we provided an application operated with a smartphone, allowing to view the operating data of the truck, e.g. battery charge status or current alarms and warnings.

WHEN TO CONSIDER AGVs?

When the extension of a production line requires a reconstruction of the facility (a greater number of conveyors)

When we want to improve the efficiency and quality indicators

When we plan a new line, e.g. one controlled centrally

In difficult work conditions

In strict sanitary conditions

When we assume a continuous expansion of the system – modular design

When the line’s expansion is to be made quickly

BASIC TECHNICAL INFORMATION

Width:

Height:

Length:

Unladen weight:

Drive: electric

Power source: battery

Max. load dimensions:

Payload:

Speed:

Maximum slope:

Full-charge time:

WHY IT IS WORTH

SHOULD SELF PROPELLED AGV VEHICLES BE APPLIED?

AMR`s are designed for those customers who are looking for a flexible and efficient transport solution. The vehicles are designed for transporting stacks of full and empty pallets and large packages. They work well in all forms of handling.

Own power sources

- High safety

- Prolonge service life

- Simple assembly and disassembly

- High efficiency

- Wide range of protection (thermal, overload, short-circuit, over-voltage, against operating errors)

INTUITIVE AND SIMPLIFIED OPERATION

- Communication with the operator proceeds by means of the HMI panel of the controller, a smartphone, or a tablet.

- The system's advantage is quick diagnostics of non-standard events.

- A serial PLC controller enables programming in a commonly used environment, TIA Portal.

EXTENDED SAFETY SYSTEM

- Laser safety scanners

- Adjusting the movement speed to the environment conditions

- Emergency buttons

- Avoiding collisions with people, with vehicles, obstacles

ANS NAVIGATION +

ANS NAVIGATION +

- navigation based on room mapping

- driving without the operator's intervention

- moving along preset routes

- processing environmental data on a current basis

- Natural Feature navigation

- the navigation system uses environmental features

- AGVs compares its location with the virtual maps of the room

- the scanners identify the structure of the space

- AGVs calculates its position and follows programmed routes

ARE YOU ARE LOOKING FOR A PROVEN CONTRACTOR?

Let us invite you to work with us - contact us

AGV SYSTEM'S

ADVANTAGES

Fast

installation

Great

flexibility

Easy

operation

Direct communication

with the network

Programming limited

to the minimum

High safety

safety

Easy integration with existing

lines

Simple interaction – a smartphone,

a tablet

Opinie

Opinie

Zobacz, co mówią nasi klienci