ROBOT-BASED LINES

FOR COLLECTIVE PACKAGING

GOOD PACKAGING – IS RELIABLE PACKAGING

SIMPLY RELIABLE

COLLECTIVE PACKAGING ROBOT-BASED LINES

Good packaging is reliable packaging. At Wikpol, we know this since forever. Our experience acquired by us over more than 30 years of designing and manufacturing packaging equipment has resulted in that our lines operate without breakdowns.

WHAT PRODUCTS ARE WE PACKING?

WE PACK DIVERSE PRODUCT RANGES, AMONG OTHERS:

- oil

- chemical products

- hygienic household products

- floor panels

- paints

- pigments

WHAT DO WE PACK INTO?

COLLECTIVE PACKAGING IS USED FOR PRODUCTS PACKED FOR RETAIL,

Cardboard boxes with flaps

Cardboard boxes with lids

Cardboard boxes without lids

Plastic containers

Displays

Trays

Metal containers

Steel baskets

ARE YOU ARE LOOKING FOR A PROVEN CONTRACTOR?

Let us invite you to work with us - contact us

Our offer

Our offer

Wikpol’s offer includes solutions verified in various manufacturing conditions

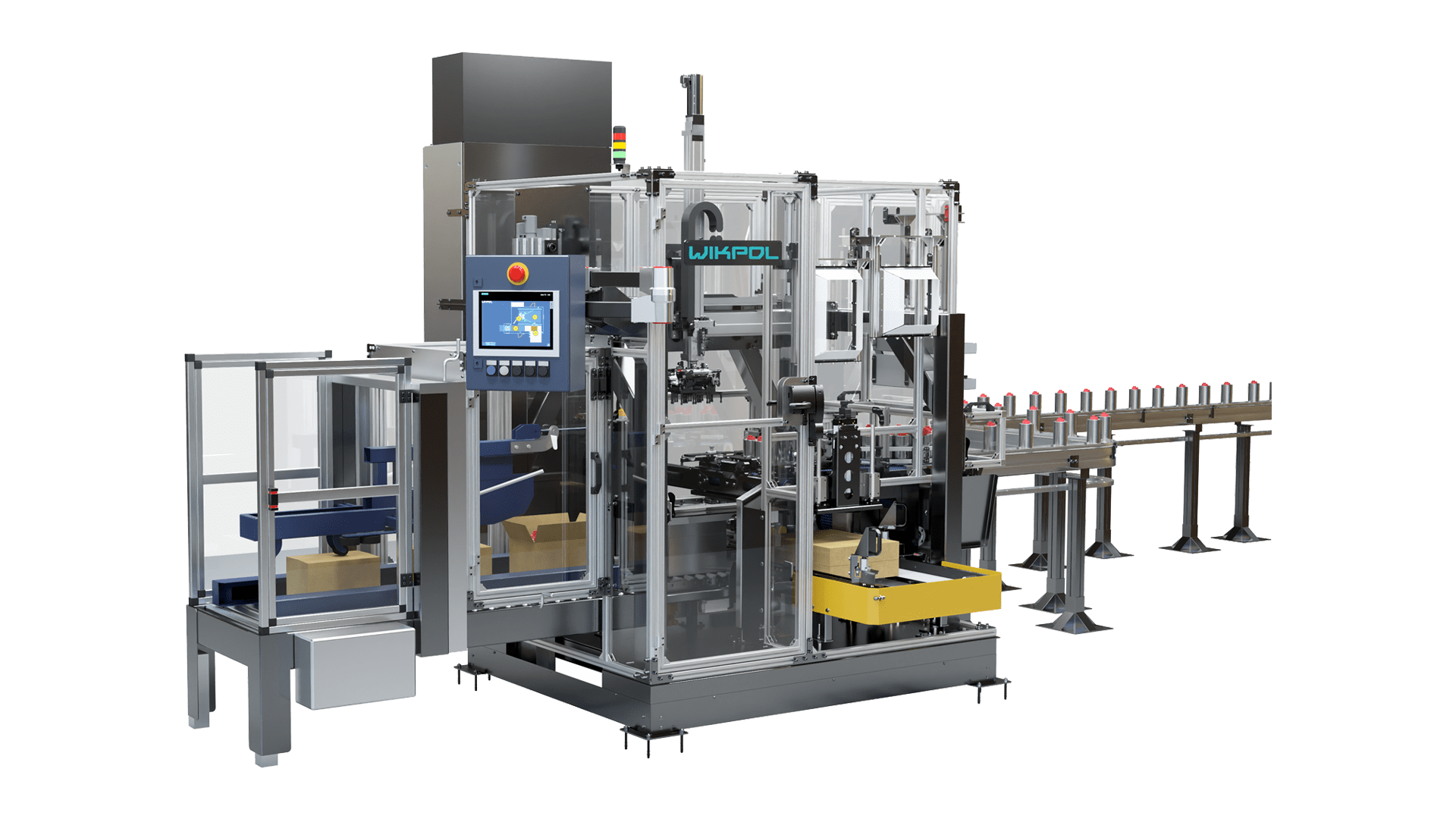

CASE PACKERS

The devices are used to pack diverse product ranges into cardboard boxes according to defined schemes. The main executive element is a robot, which picks up layers of accordingly positioned products. The robots are equipped with mechanical or vacuum grippers. The structure of the grippers has optional replaceable adapters for various types of assortment. The case packers can be equipped with a magazine for cardboard boxes with an automatic forming and guiding module and with automatic gluing modules. With the clear interface of the panel, the device might be configured intuitively. The case packers may be deployed quickly, and at possibly low costs.

Package mixing lines

The lines are intended for mixing different types of products in commercial packages. The lines include cells of cooperating delta and scara robots, equipped with vision systems. The robots’ job consists in arranging the retail goods being packed precisely: front /back, up/down, and then in picking up the set of products according to a sequence saved in the current production plan. The ready-made sets of products are placed in pre-formed packages by a robot equipped with a special gripper. The line is being operated intuitively by means of a central operator panel (computer) with the SCADA system.

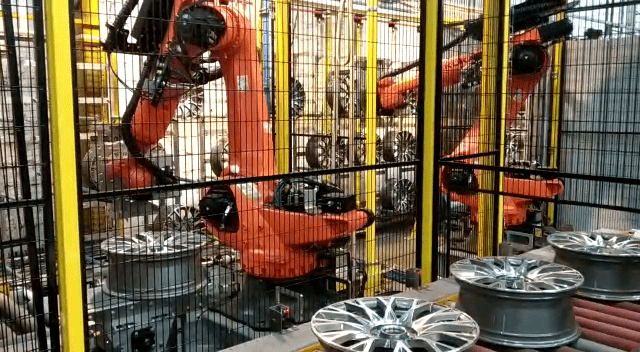

CUSTOMIZED LINES

The collective packaging lines are adapted to pack goods of different shapes, formats and weights into different types of cardboard boxes thanks to the special design of the grippers. A single robot may simultaneously pack more than one type of products into different types of packages, close the cardboard boxes, or put lids on. The packaging lines are usually equipped with selected functions, such as: forming cardboard boxes, quality control, palletization, buffering, intralogistics. The lines are safely linked with third party systems (VPN). The packaging process is optimised, ensuring an increase in the productivity, a reduction in the costs, and a high quality to our clients.

OUR PROJECTS

OUR PROJECTS

Take a look at the examples of the problems we have solved based on specific implementations

Do you have any questions?

Get in touch with us in any way you find convenient

WHY IT IS WORTH

TO ROBOTIZE COLLECTIVE PACKAGING PROCESSES

An increase in the capacity, productivity, reduced costs, improved product quality, increased flexibility, stabilized processes – these are example benefits that businesses may obtain by means of robotization.

ADAPTING TO PRODUCTS

CUSTOM DESIGN

SAFETY

FEATURES, AND ADVANTAGES

WHAT ARE WIKPOL'S COLLECTIVE PACKAGING LINES LIKE?

04.

Integrated with IT systems

Wikpol’s lines are integrated with third party systems. For instance, SAP is connected via…

05.

With an intuitive interface

When designing the line, we pay careful attention to occupational comfort, which includes different fields in the field of ergonomics…

06.

Employing modern technology

At Wikpol, a long list of solutions is utilized based on modern…

08.

Simple in operation

The software of our products is continuously developed to simplify the operation as far as possible…

10.

Operating continuously

One of the important arguments for robotizing a manufacturing plant is…

11.

Proven in many industries

Wikpol has completed numerous projects in the scope of robot-based palletization lines…

12.

Custom designed

The correct identification of the needs is crucial in creating an optimum solution – such as…

What benefits

ARE OFFERED BY THE PALLETIZING LINES?

Great flexibility of the line

High-safety level

Increasing production indicators:

– effectiveness

– capacity

– manufacturing quality

The ease of manufacturing scalability

Significant stabilization of manufacturing processes

A reduction in the costs resulting from:

– pauses and stoppages

– qualitative shortages

– absences

A BROAD RANGE OF ACTIVITIES

THE COLLECTIVE PACKAGING LINES MAY BE EXPANDED BY A NUMBER OF FUNCTIONS:

- marking or labelling the products

- controlling the labels for compliance, correctness

- forming trays, displays, and cardboard boxes

- mixing different types of products in multipacks

- product palletization

- control of product weight or shape and discrimination of out-of-tolerance pieces

- controlling the packages for correct closing

- applying the corners, washers, spacers, and lids on the pallets

- foil wrapping and labelling the pallets

IN WHAT SITUATIONS

ROBOTIZED PACKAGING SYSTEMS?

Opinie

Opinie

Zobacz, co mówią nasi klienci