We are at your disposal

We will be glad to help You select the best solution.

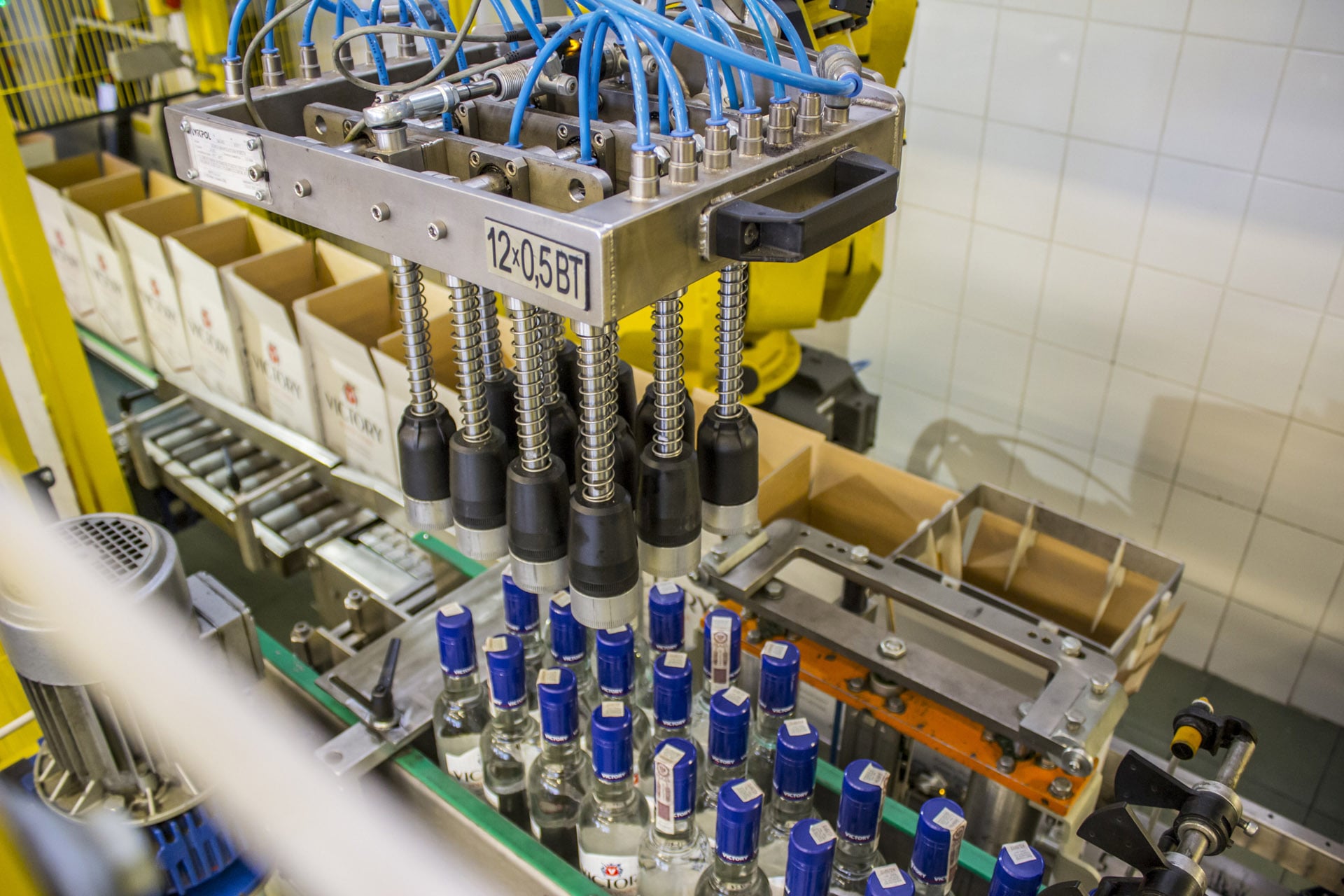

Four types of glass bottles filled with alcohol beverages, packed into cardboard boxes with flaps.

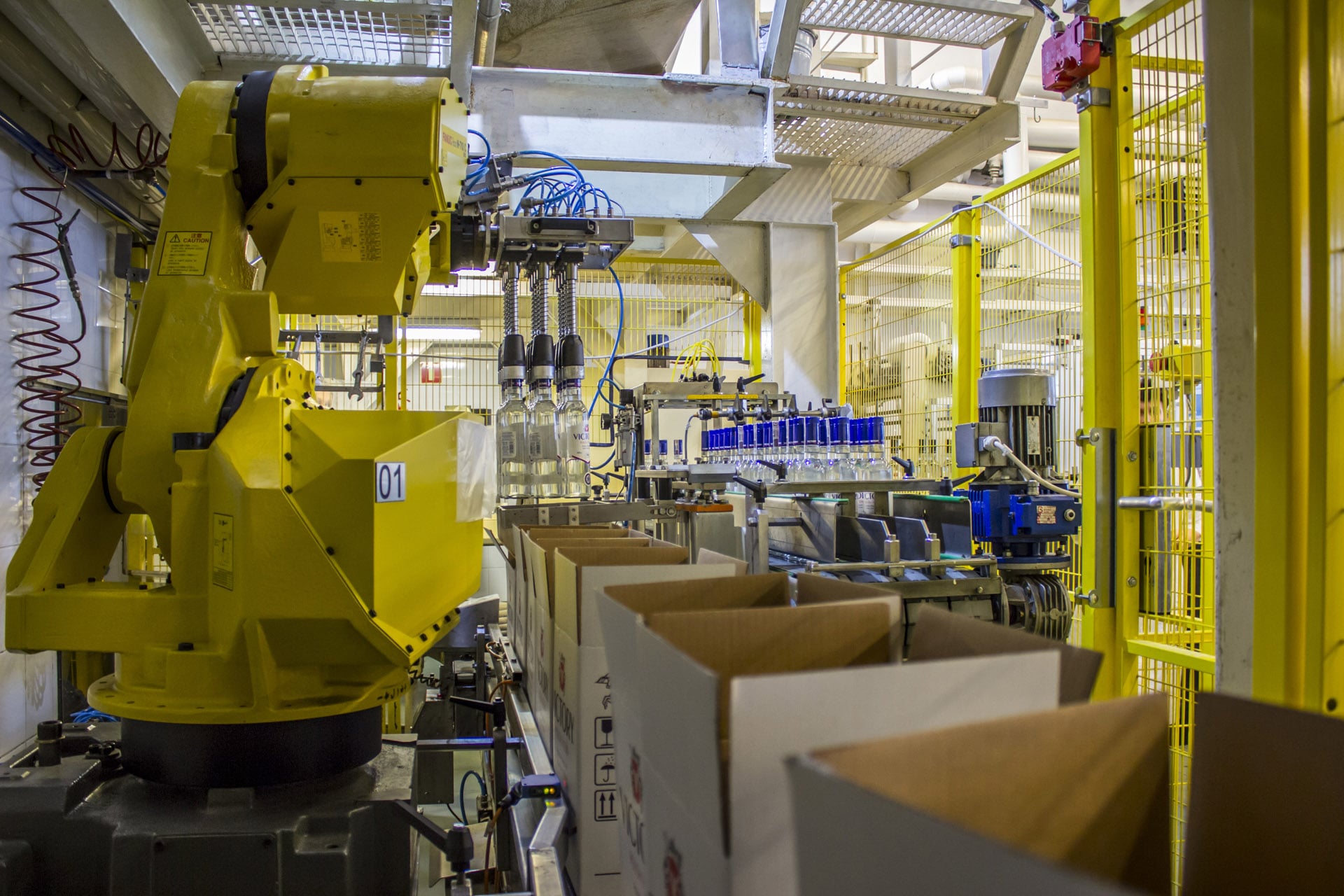

The objective of the investment project was to increase the capacity of the packing process, to ensure collecting the entire production from one production line, with the option of handling the second lane in the future. Another assumption was to adjust the robotized packaging station to a very constrained working space, without the need to reconstruct the existing production plant. The dimensions of the robot's cell: 208x250x220 [cm]. An important aspect associated with the robotization of the packing process is a radical reduction of broken glass when placing the bottles into cardboard boxes.

The maximum output of the packaging station is 450 cardboard boxes// hour and is adapted to the capacity of the production line.

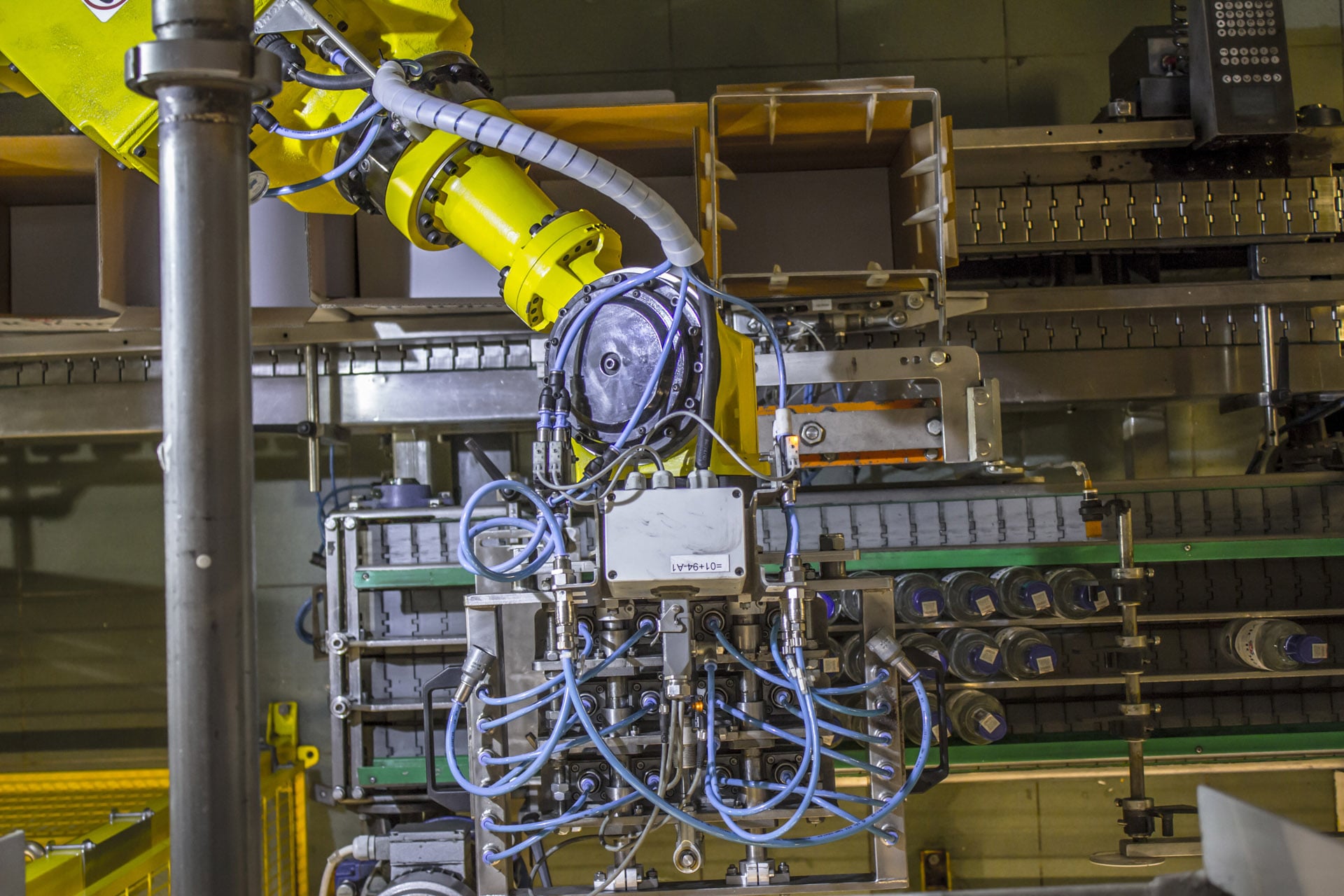

In order to match the working space available, the line employs a six-axis Fanuc Robotics robot type M710iC with a range of 2050 mmm. The robot has been equipped with a special gripper designed to pick up bottles from the existing picking and packing module and to stack them in the cardboard boxes.

The head picks up a whole layer of bottles in one cycle, which constitutes the content of a single cardboard box