We are at your disposal

We will be glad to help You select the best solution.

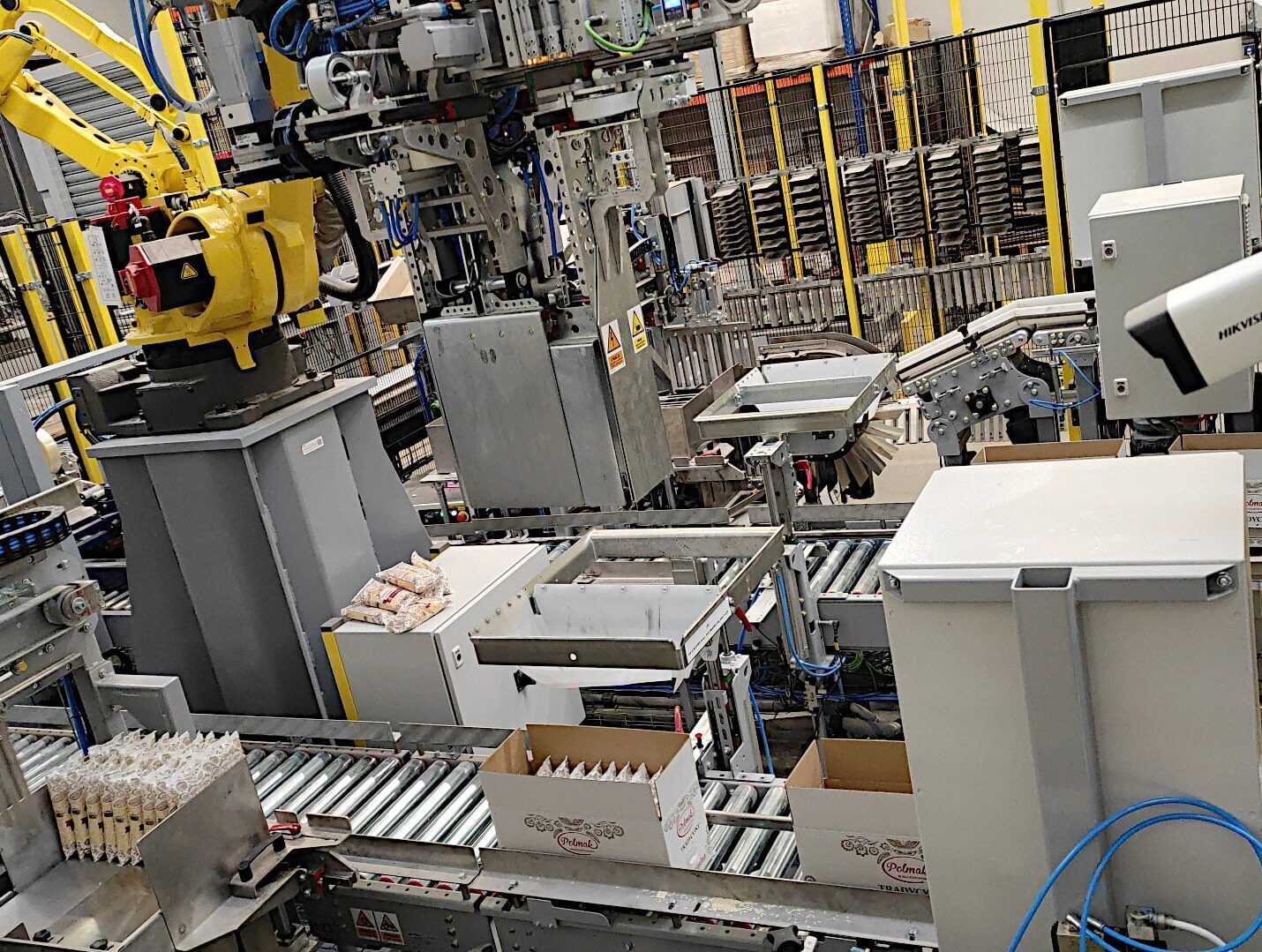

Pasta packed into bags of different formats and basis weights.

1. Increasing the production volume by launching new production lines

2. Eliminating jobs troublesome for people

60 packages/min.– one lane

In the line, three industrial robots operate and serve three different production sections:

The CARDBOARD BOX FORMING ROBOT picks up flat cut elements, forms boxes, and moves the prepared cardboard boxes to the right conveyor towards the packing robot. Additionally, it handles the packages at the cardboard box gluing station.

THE PACKING ROBOT collects and places two product kinds in the cardboard boxes at the same time.(The cardboard boxes may be of various types.) For this purpose, the robot's head automatically re-fits itself for each pasta bag held. In the case of displays, the robot closes the cardboard boxes with lids.

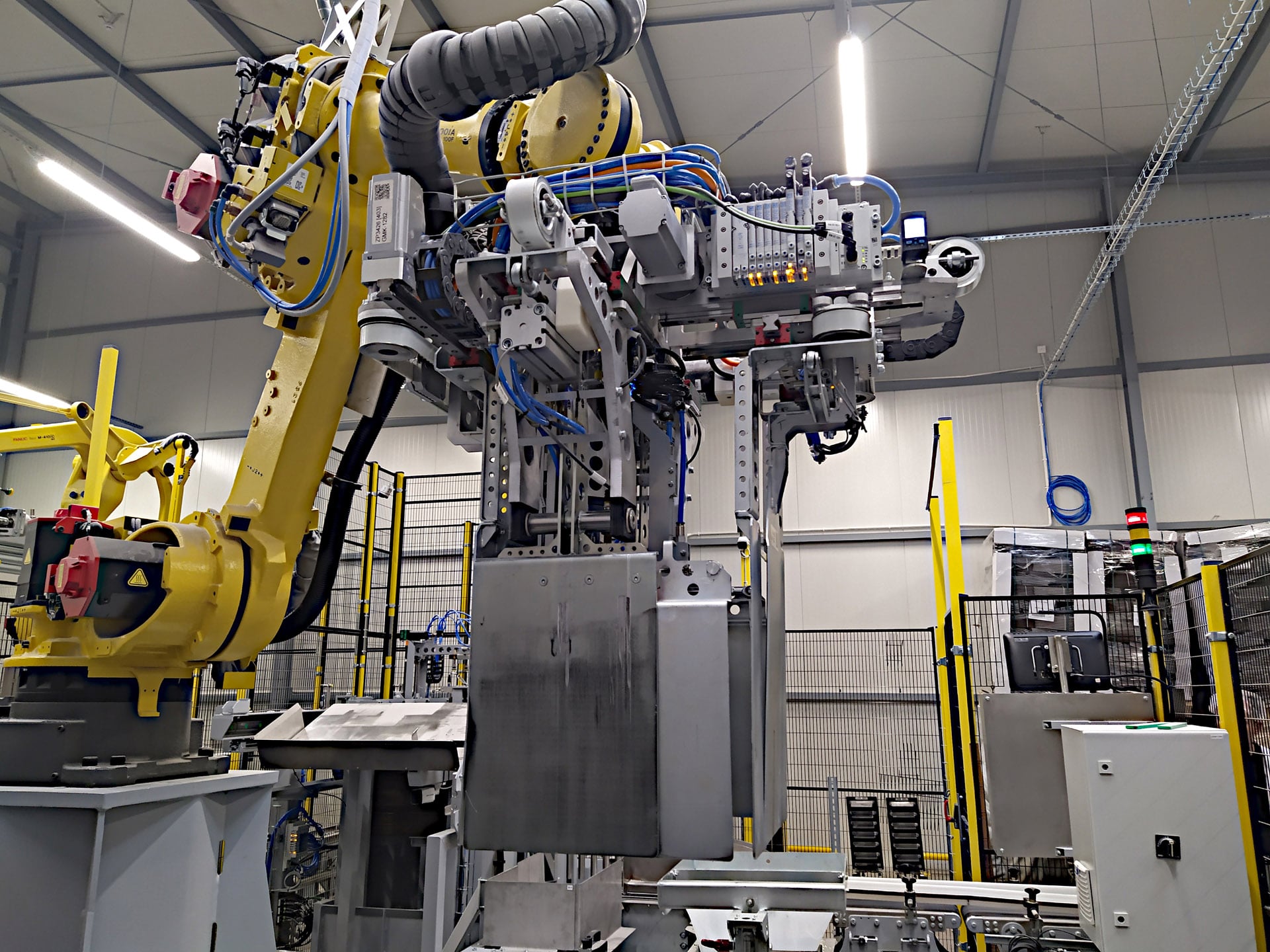

The PALLETIZING ROBOT is equipped with a multi-purpose gripper, which:

- picks up full rows of cardboard boxes or their number that matches the current pallet plan

- it collects and places dividers in accordance with the current scheme

- collects and positions empty pallets

The robot-based packaging and palletizing line at the same time picks up products from two production lanes using two transport routes. At each conveyor lane, there could be a different type of packages (in terms of the dimensions and weight), being delivered at different capacity in a continuous cycle, or with the option of dividing and buffering.

The collective packaging stage starts with controlling the correctness of the unit package weight and the presence of metal contaminants (a scale-detector and a discriminator).

Then, the products are directed to specially built picking and packing module which, among others, change the arrangement of the bags from horizontal to vertical.

Another step is collective packaging, which, although performed in layers, proceeds slightly differently for each type of packages; just like the closing of full packages.

At the same time, cardboard boxes are formed, and sealed at the bottom.

The packed, closed/sealed cardboard boxes are being transferred to the labelling machine, from where they go to the palletization area. Here, the robot places two different assortments on two pallets at the same time together with dividers, and it arranges the cardboard boxes with the label facing outside. The user can easily program themselves the templates of arranging on pallets, with the intuitive Alpa-ADD app.

The robot-based packaging and palletizing line is characterized by smooth, continuous operation. The robots installed in each of the three areas simultaneously pick up and form/pack/stack different product kinds. The system is adapted to a diverse range, and also to new products, which may appear in the future.