We are at your disposal

We will be glad to help You select the best solution.

PET bottles with a volume of: 1 l/ 1.5 l/ 2 l/ 3 l/ 5 l. The bottles differ in shape, and in additional elements (with or without handles).

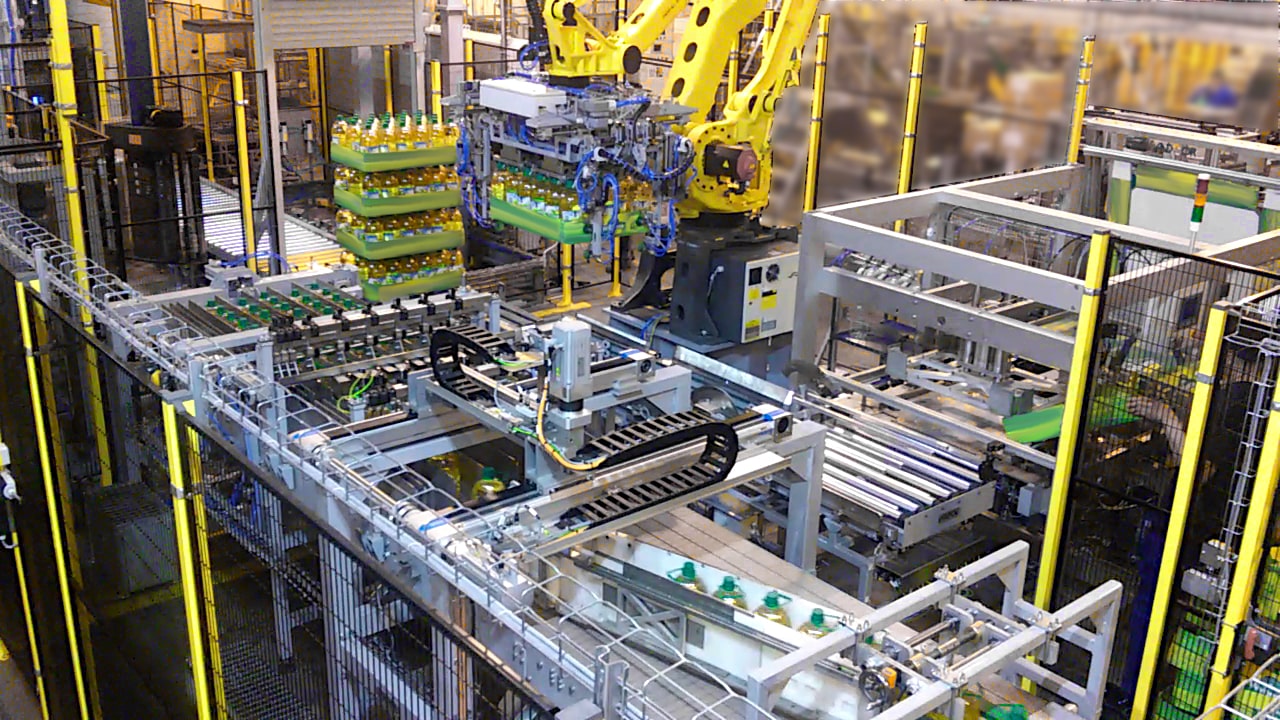

The robot-based packaging and palletizing line reaches a capacity of 11,000 bottles per hour. The capacity is flexibly adapted to the production output, which is different, depending on the volume of the bottles.

The Client has expanded the manufacturing capacity of the plant, which has resulted in the need to adjust the packaging and palletizing area to the new conditions. Keeping the existing, traditional model would involve the need to expand the space intended for the packing and palletizing processes.

The robot picks up a layer of products from the picking and packing module, and places it in a ready-made, positioned display. Then, it moves the display onto a dhp pallet. After laying a full pile, it places "a hat" on it in the form of a display inverted by 180o.

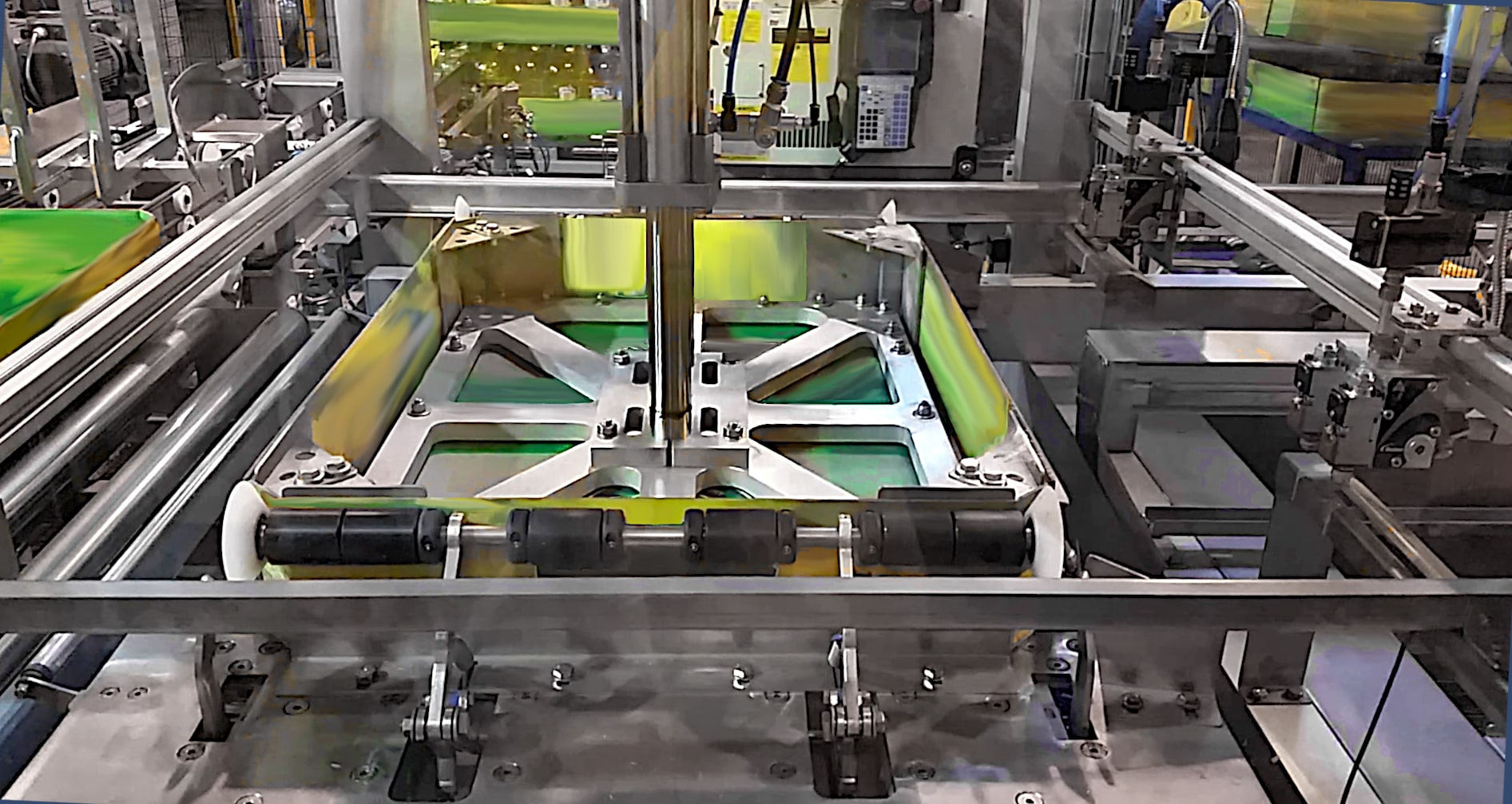

The specialized designs of the robot's gripper and of the picking and packing module make it possible to pack and palletize five types of assortment.

Additionally, the picking and packing module helps pack the bottles in the layers as tightly as possible, and flexibly change the arranging templates depending on the assortment type (For certain volumes more than one configuration diagram has been provided.) The bottles can be grouped in 11 rows, simultaneously taking account of two forming row directions – lengthwise and crosswise. On the other hand, the module for positioning holders at the screw caps ensures their positioning in a specified arrangement.

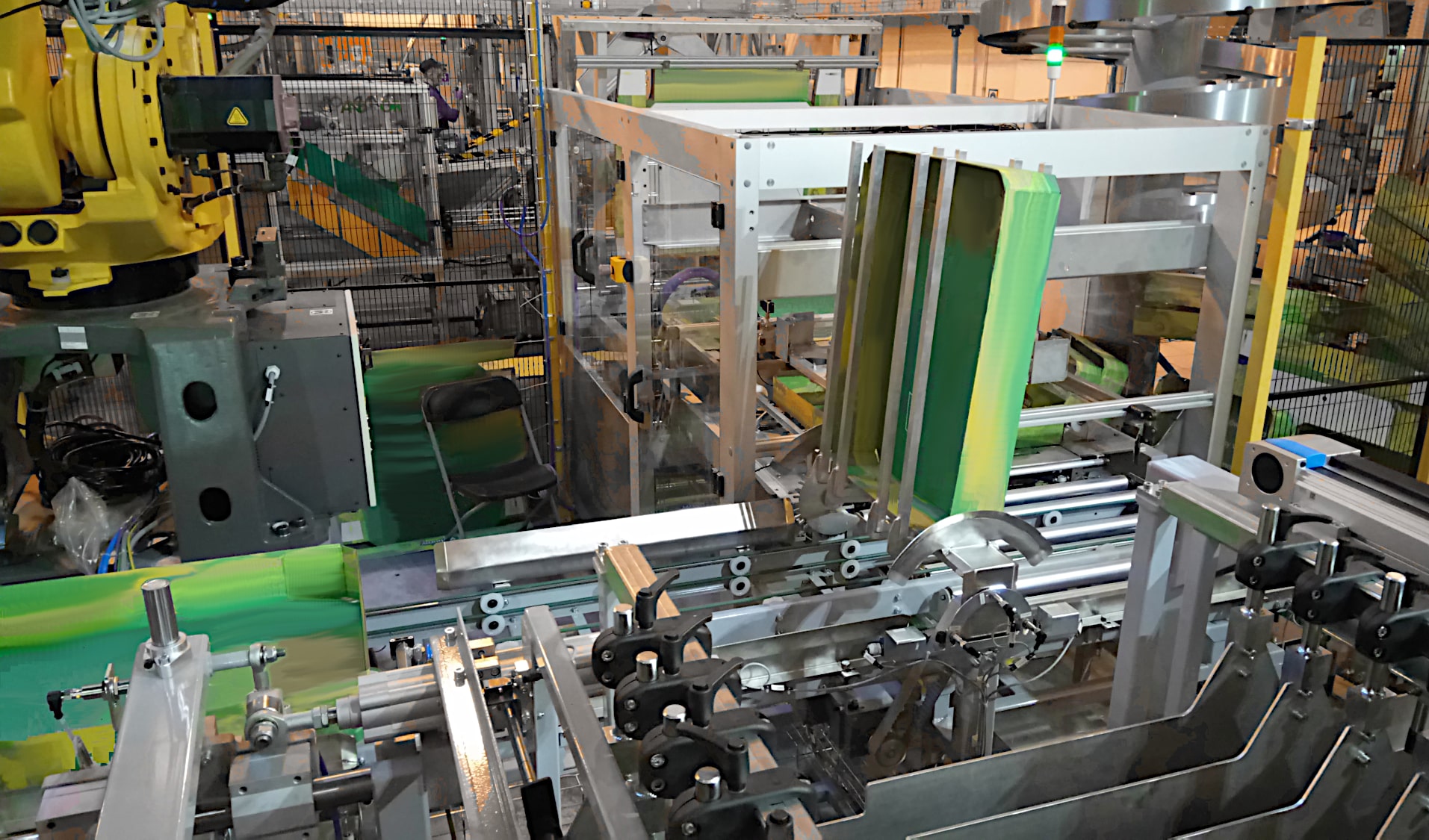

The line packs and palletizes products fed from five independent manufacturing lines. To maintain the existing organization of the production process, the system for transporting the products to the robot's station was raised to a height of 2.5 m and equipped with removable conveyors.

Additional tasks performed on the line: