We are at your disposal

We will be glad to help You select the best solution.

The modernization combined with an extension of the existing palletizing line with an industrial robot consisted in preparing a technological design, and delivering, installing, and starting up new devices, including, among others:

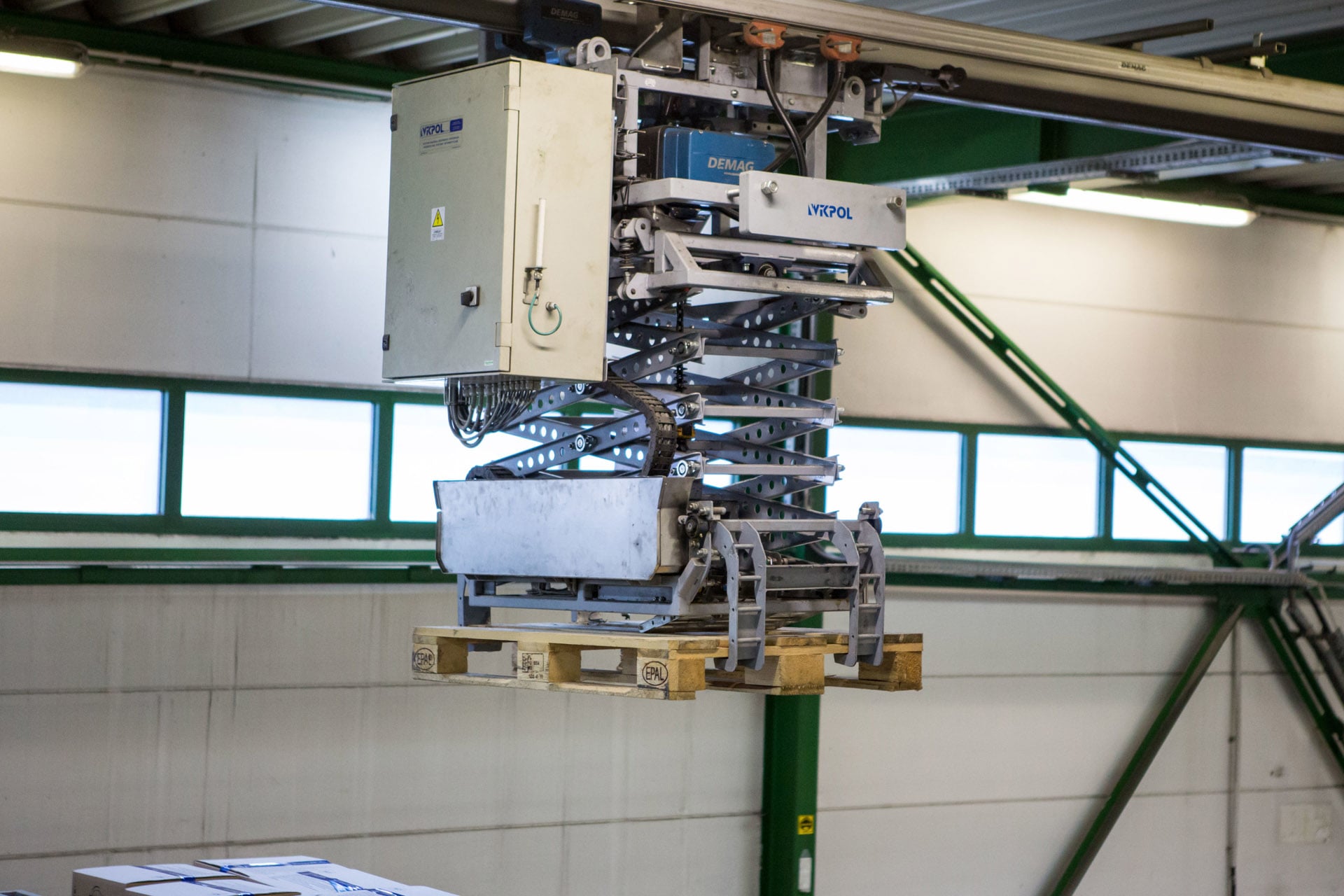

Wikpol has modernized the gripper and the traffic rails of the FANUC Robotics R-2000iB/165F industrial robot, and has delivered a new software app, which takes into consideration the extension of the line both in the scope of PLC programming, and of the industrial robot. Wikpol has expanded the existing control module for the cardboard package transporting and palletizing system, and delivered a new PLC control cabinet.