We are at your disposal

We will be glad to help You select the best solution.

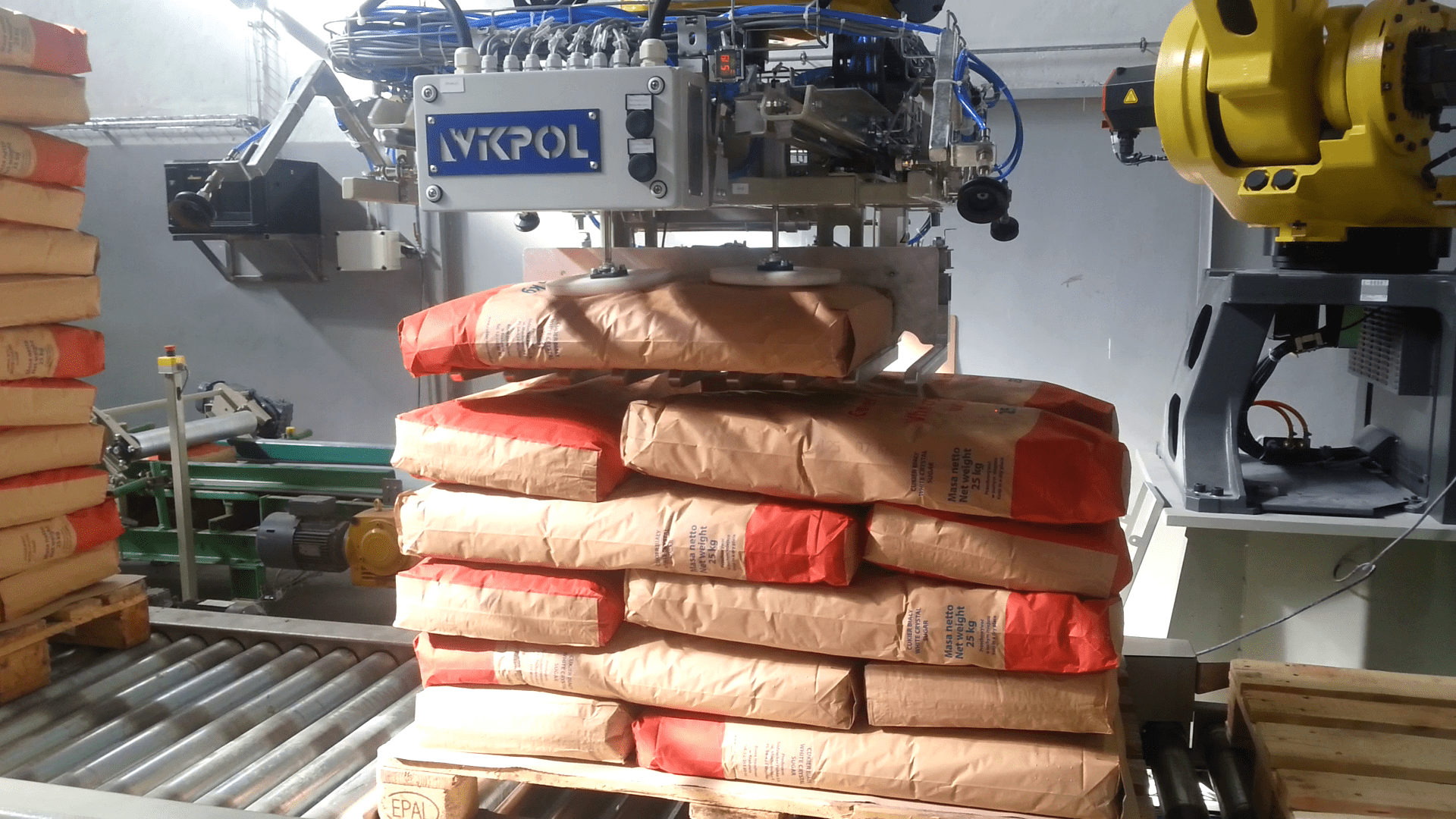

Nominal capacity:

25 kg bags: 11 tons/hour, namely 440 pcs./h

50 kg bags: 15 tons/hour, namely 300 pcs./h

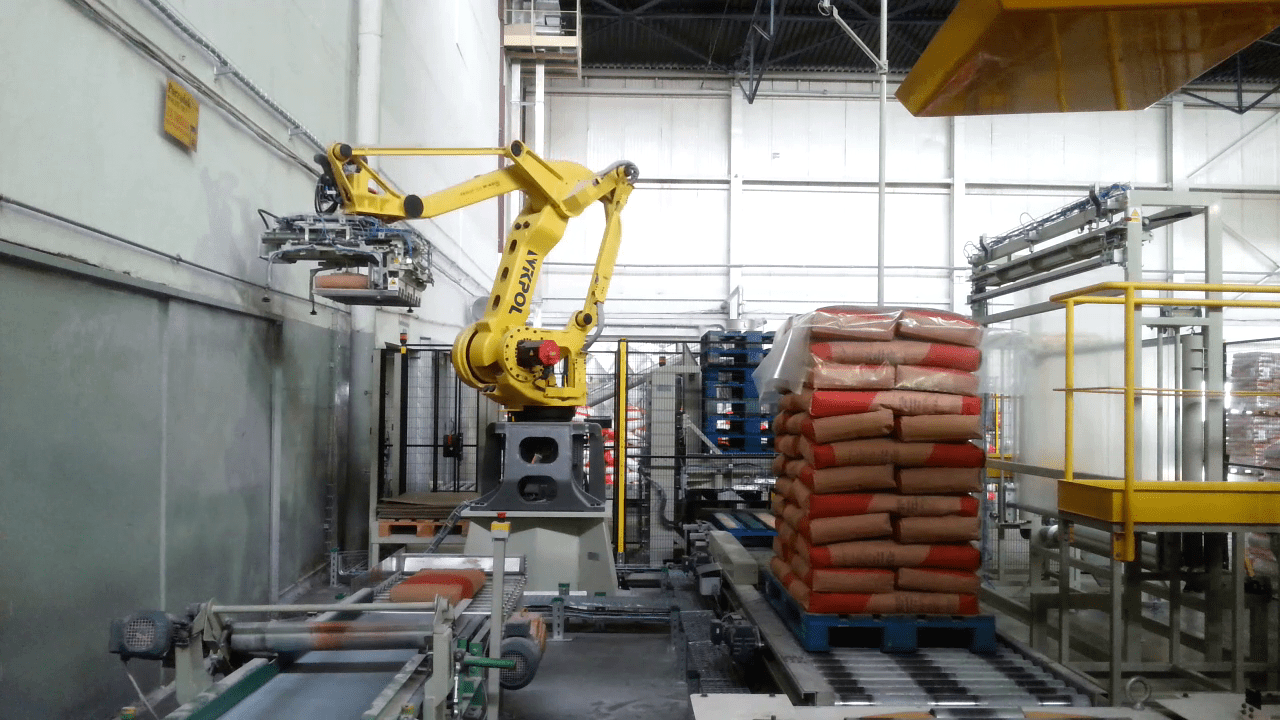

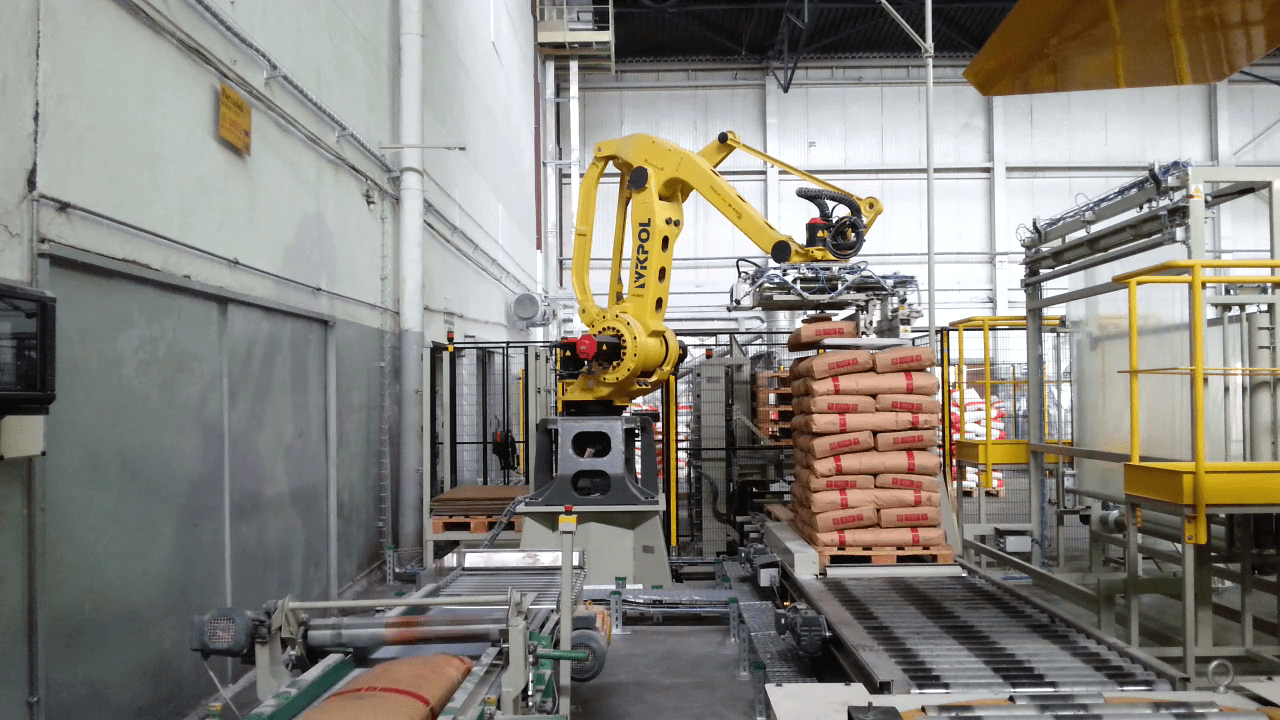

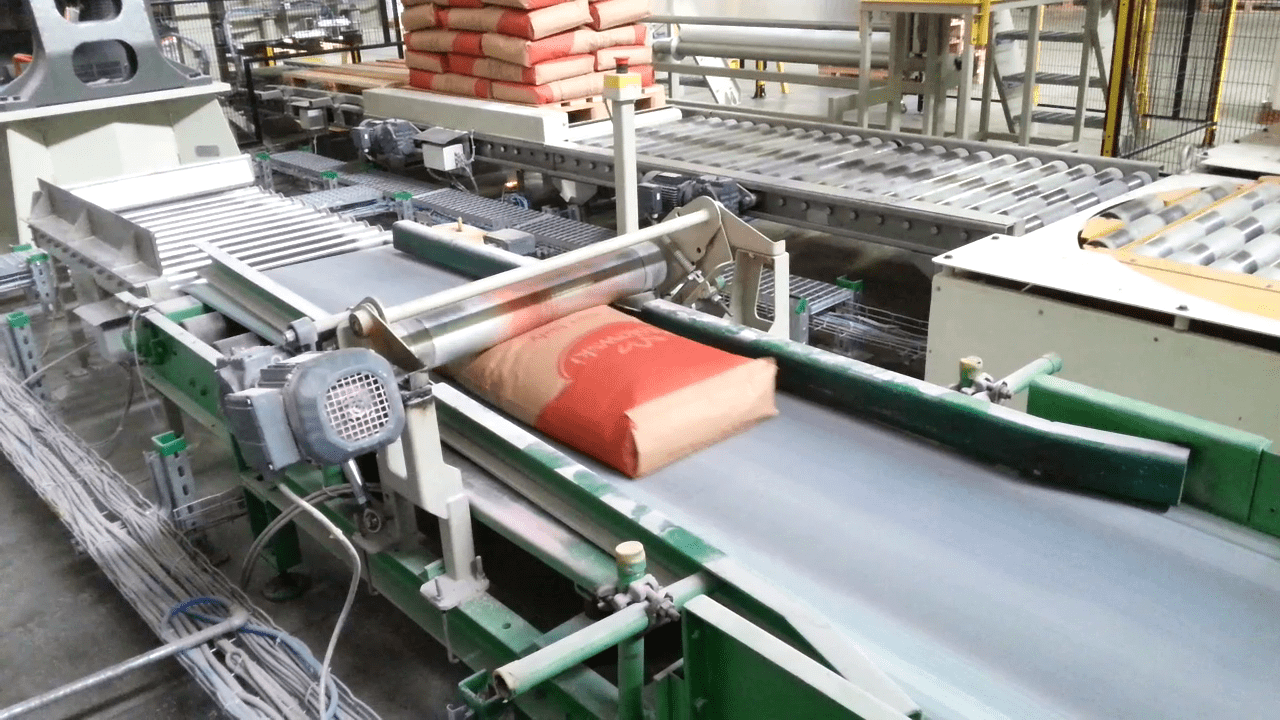

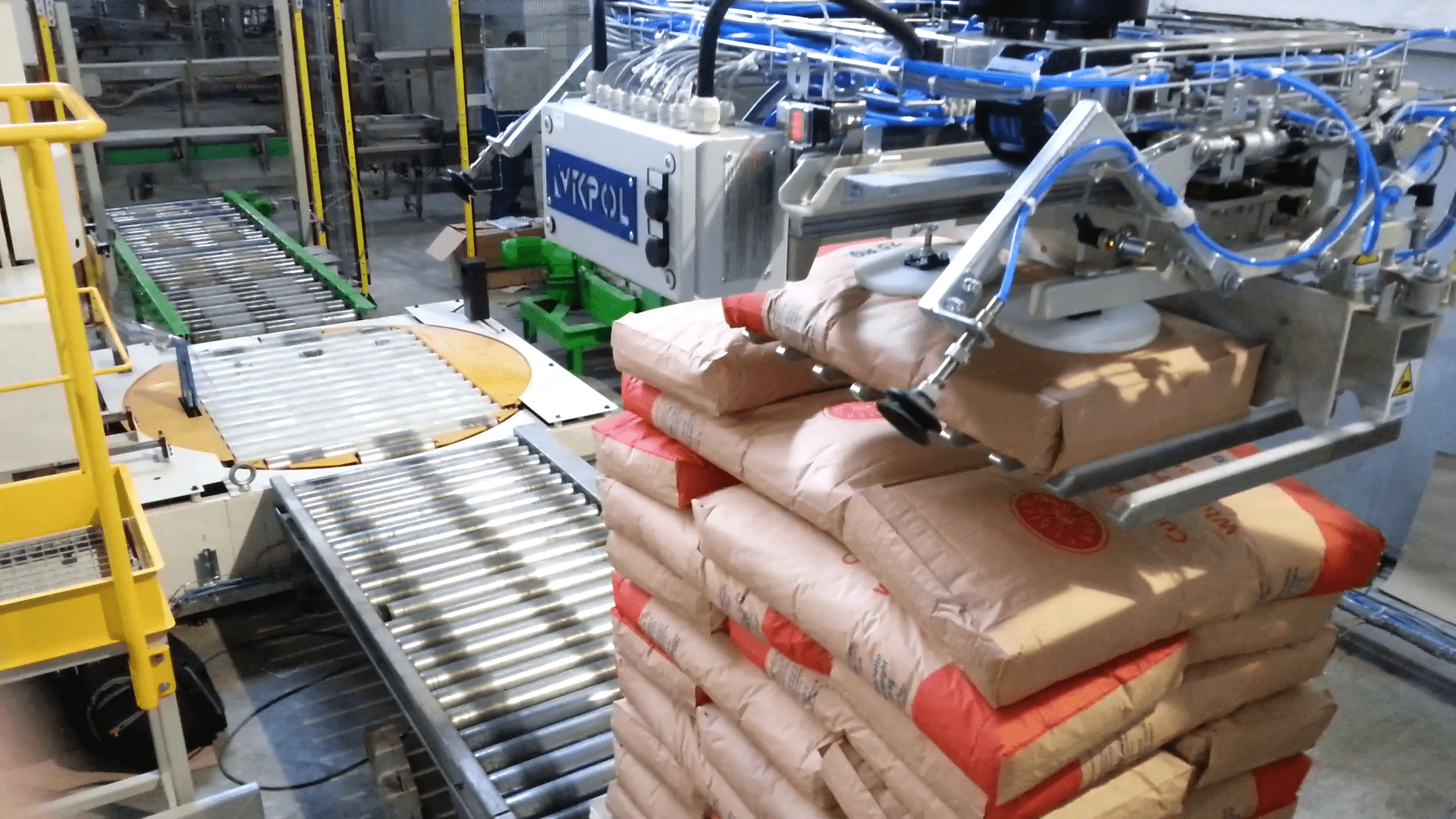

An empty pallet is moved to the workplace zone of an industrial robot which palletizes bags by a conveyor from an automatic pallet feeder. The robot picks up a single cardboard spacer from the magazine, and places it at the bottom of the pallet. The magazine is topped up manually by the personnel. Then, the robot, using its gripper, proceeds with stacking (palletizing) bags on the pallet by picking up one bag at a time and placing it according to a previously programmed sequence. After filling the pallet up, the last layer is covered with a foil divider. The robot also unwraps foil from the roll, trims the foil divider down to the suitable length, and then arranges the foil divider on the top of the pallet before it moves to the wrapping module, the robot uses a head designed for this job. The pallet with the bags arranged is being wrapped by a pallet wrapper. The completed pallet is moved by a roller conveyor to the place where it is collected by the personnel.