We are at your disposal

We will be glad to help You select the best solution.

The goal of the expansion and modernization of the palletizing line for cardboard packages was to increase the capacity up to 85 packages a minute (by 25%), and to increase the number of assortment items that can be palletized at the same time by additional eight products - up to 35 SKU in total. The investment project consisted in:

The products are being delivered to the palletizing line from two production areas, and they are transported from the packing machines' level to the level of the sorting system and the palletizing stations by elevators. The products from all the elevators are moved to a single shared conveyor. The packages are being distributed to selected palletizing sites by a sorter, in line with the production order assigned based on the bar code applied on the package.

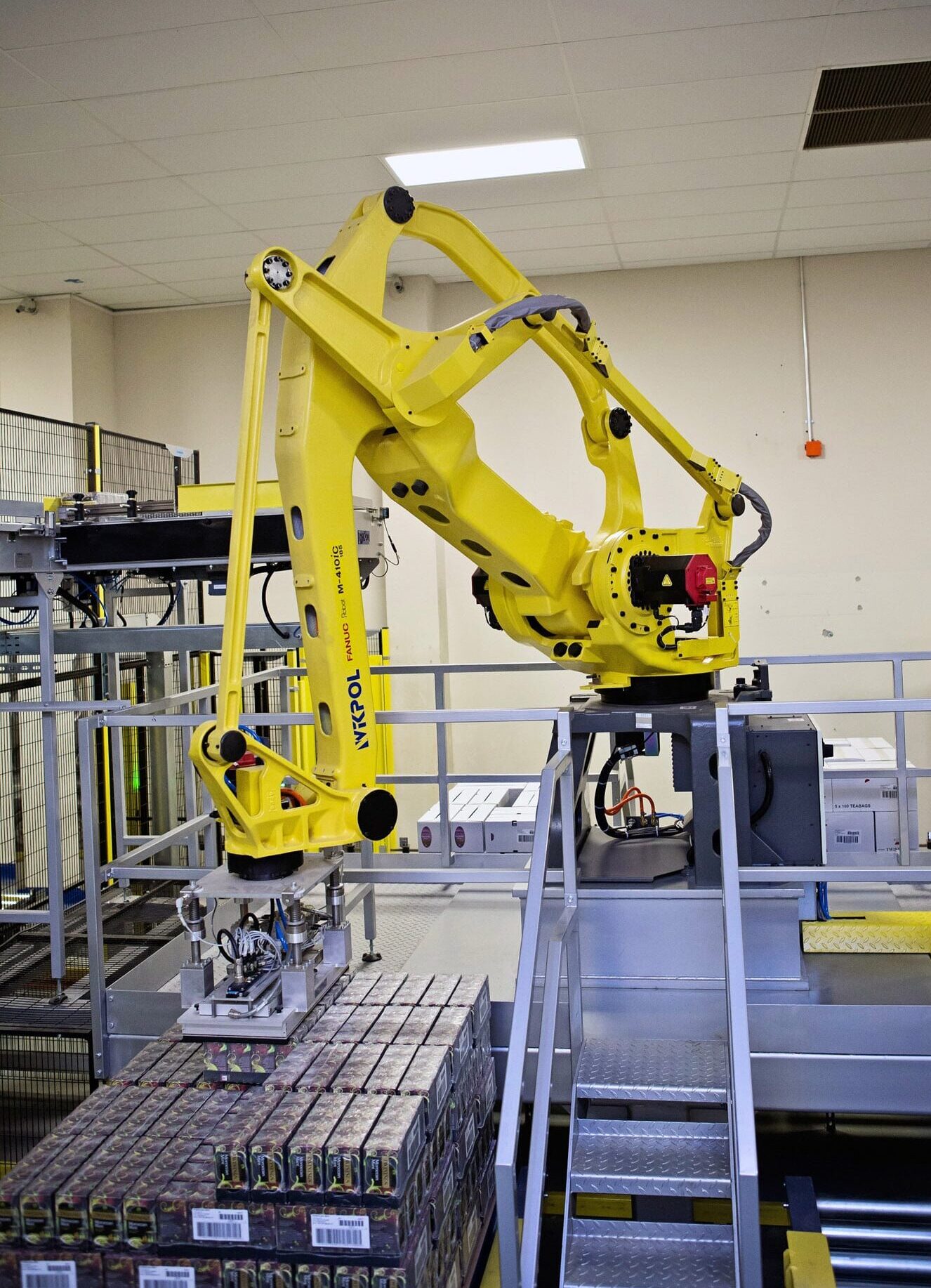

Each palletizing station places simultaneously four different products on four pallets types (taking into consideration the pallets' dimensions and colours). The robots pick up packages using vacuum heads.

An important element of the palletizing line is the module for feeding empty, collecting and wrapping loaded pallets with a control system based on a single PLC controller. The empty pallets are moved by an industrial robot and a special manipulator which makes it possible to transport pallets collision-free to the central section of the line. The empty pallets are being distributed with two trolleys with roller conveyors installed. On the other hand, the loaded pallets are collected with the use of four trolleys which travel along particular palletizing stations. Wi-Fi communication modules are used to communicate with the trolleys. The safety system has been designed so that an intervention of the staff at a given station does not stop the operation of the others.

The loaded pallets are moved away automatically to the pallet wrapping area, where two automatic ring type wrappers have been installed (and in the normal mode one does not work and is treated as a back-up, in case of a failure of or servicing at the main wrapper), with an automatic corner and top spacer application module, which is based on a FANUC Robotics industrial robot. Applying corners on a station independent from the main wrapper made it possible to use a lower capacity wrapper than those required for integrated systems. Logistical labels are applied on two side surfaces of a full pallet. Labelled pallets are collected by a forklift truck.