We are at your disposal

We will be glad to help You select the best solution.

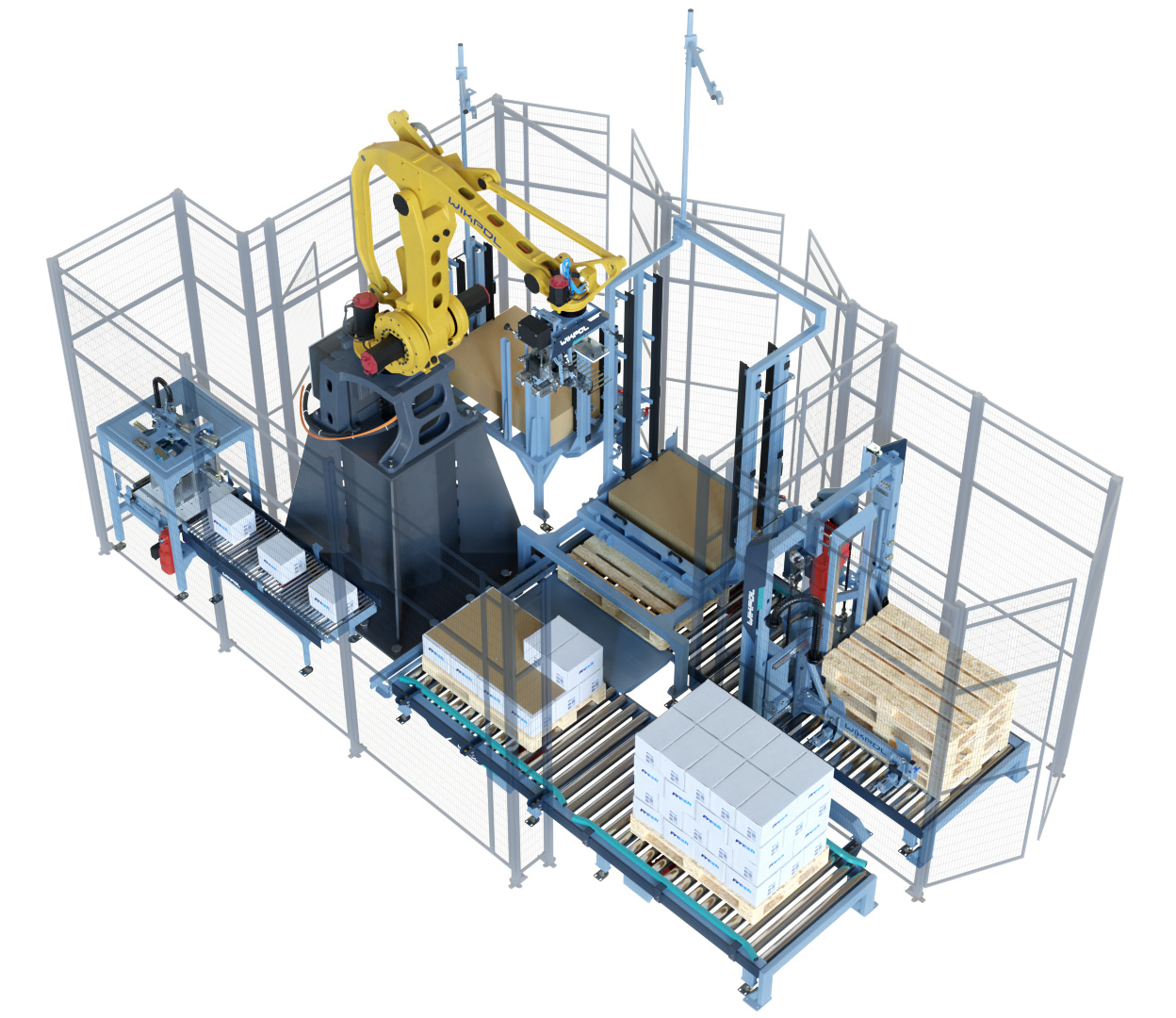

The compact palletization cell is offered by Wikpol to companies who look for a reliable and flexible automated palletization device, which could be deployed at a plant quickly and at possibly low costs of the investment projects.

The experiences of the users from different industries confirm numerous benefits resulting from the compact palletization cell. The most important of them are the ease of adjusting the cell to the production needs, minimized expenses, and a fast return on investment. The customers also emphasize positive outcomes when it comes to operating the station, including the high capacity and efficiency, reliability and simple, intuitive operation.

The high flexibility of the palletization cell is a result of the application of an industrial robot equipped with a technically advanced gripper. The head is adapted to palletizing cardboard boxes or multipacks of different formats and different weights, and the maximum weight for the basic model reaches 60 kg. The average capacity of the cell is 30 packages a minute. It may, however, differ depending on the size of the packages and the stacking template: from 8 packages when collecting individual units to more than 30-40 packages collected collectively. The system can grab/carry paper spacers in one cycle together with packages. The capacity of the cell and the scope of its tasks could be adjusted to the user's individual needs.

The operation of the cell is simple, and utilizes an intuitive interface. The specialized software app for the creation of palletization templates brings similar benefits. It gives the user full independence, and the unlimited ability to expand the product stacking schemes.

The robotized palletization cell has been designed for intensive and failure-free long term operation. An important support for its efficient operation, next to its optimized and proven design, are the diagnostic modules and the remote maintenance service, on the basis of industrial VPN.

Next to industrial robots and current technological achievements in designing, driving, controlling, and safety, the robotized compact palletization cells also feature the newest IT and communication solutions, which make it possible to include the station in the plant's information circulation system and to manage the production processes remotely. The data is exchanged with other systems, among others, through TCP/IP and OPC UA protocols. It is an important information for companies that implement Industry 4.0 solutions.