We are at your disposal

We will be glad to help You select the best solution.

Line's capacity: max. up to 52 baskets/min.;

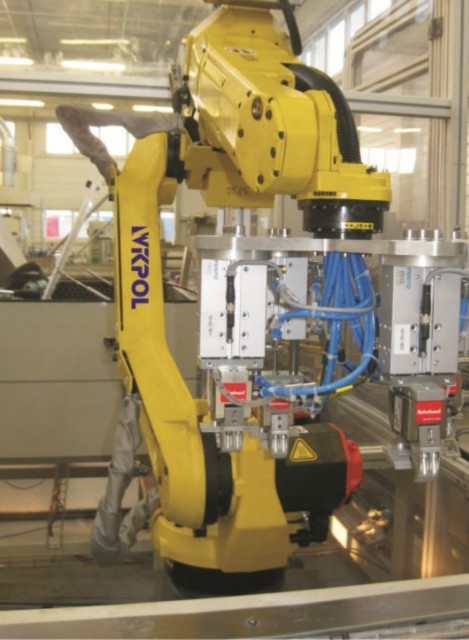

A Fanuc Robotics M10iA robot, equipped with a special gripper, picks up a basket from a belt conveyor and places it in a blister pack made in a nearby device. The baskets are picked up separately, and placed in the blister packs, four at a time.

The robot picks up the baskets from the existing conveyor and puts into the blister packs located on the nearby conveyor.

Basket mass: 57 g.

The synchronization of the robot's operation with the devices operating on the line, namely the conveyor which moves the baskets, and with the blister pack conveyor, and with additional sensors (checking the presence of hooks – in the case of a missing hook, the robot does not put the basket into the blister pack), and the robot's controller was carried out using digital input/ output modules integrated with the robot's controller.

A "line tracking" advanced system installed in the robot for tracking the movement of the belt makes it possible to track and handle details moving on the conveyor. It consists of an encoder which synchronizes the cooperation between the basket conveyor with the robot's operation.